Corrugated Cardboard

Corrugated Cardboard

Corrugated cardboard is the cardboard that is most likely associated with parcels and movings. The combination of corrugated layer and top layer makes corrugated board an extremely reliable material for a wide variety of constructions.

Corrugated board - Cardboard with the flute

Corrugated board is the material, that envelops all the beautiful things, that we have sent home. We probably have the most to do with corrugated board, when we tear open and dispose of packaging. You can buy corrugated board from us just like the corrugated board factory created it: undamaged, unprinted and unglued, large and smooth.

This is what you can do with corrugated cardboard

Corrugated board convinces with lightness and stability. In addition, corrugated board is often a recycled product, can be procured at low cost and is easy to process. These qualities have made them the world's first choice when it comes to packaging. Hardly any move can be made without corrugated cardboard boxes and the boom in mail order would simply be unthinkable without corrugated cardboard packaging. In addition, corrugated board is also used for handicrafts, working models, dioramas, mock-ups, presentation backgrounds in the Shabby look, for boxes or for the sign at the demo.

What is corrugated cardboard?

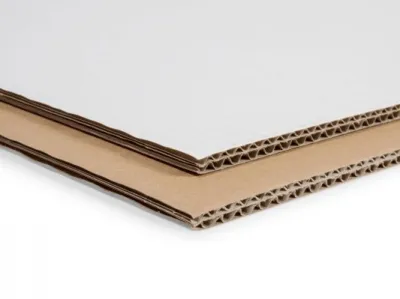

In contrast to solid board, which simply contains the raw material and its properties, corrugated board is a construction in which the properties of the material are used wisely. Every corrugated board consists of at least one corrugated paper and at least one cover paper. Testliner (waste paper cover paper) or kraftliner (very stable paper made from long virgin fibres) are used as cover papers, the corrugation in the middle usually consists of a lignin-containing and thus quite stiff corrugating medium. The corrugation and the top layer are glued together by a starch-containing glue. The stability of the corrugated board results from this bond, as the corrugation and the cover paper stabilize each other through the bonding and both can no longer react to the application of force through evasion. Variations in this structure are mainly due to the wavelength, height and thickness of the papers used and lead to different stability and weights.

Single sided corrugated board vs. double sided corrugated board vs. double sided corrugated board

Basically, we distinguish between corrugated board covered on one side and thus open on the other, which we call "one-sided corrugated board", and corrugated board covered on both sides, which we call "two-sided corrugated board". The corrugated paper that gives the paper its name is either covered or open. In addition, there is another variant of corrugated board, which consists of several layers, such as double corrugated board.

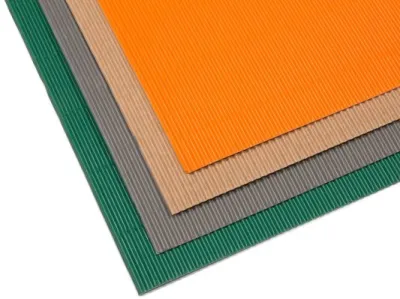

Single sided corrugated board

One-sided corrugated board shows us the corrugated paper and thus the regular corrugated structure, which is suitable for a number of handicrafts and design tasks. Therefore, single-sided corrugated board is also available pre-dyed in many attractive colours. The most important characteristic of single-sided corrugated board is certainly that it can be bent parallel to the corrugated structure. This property clearly distinguishes it from double-sided corrugated board, which cannot be bent in any direction.

Double-sided corrugated board

A rigid construction is created by sticking cover papers to both sides of the shaft. The resulting sandwich absorbs forces from all directions in case of doubt due to deformation and even punctual damage does not lead to failure of the whole. This makes corrugated board covered on both sides so popular as packaging material.

Double corrugated board

As the next development of the sandwich construction described, several layers are glued to each other alternately. The double corrugated board is certainly the best known representative: Three cover papers and two corrugated papers arranged between them are glued together. If one imagines that several different corrugated papers and several different cover papers can be combined, one suspects that the number of variations on the market is quite large. Many are standardized in DIN 55468.

This is the perfect wave

Depending on the thickness, the dimension of the corrugated papers varies. Roughly speaking: The thicker the corrugated board, the greater the wavelength and the higher the amplitude of the corrugation. A microwave corrugated board with a thickness of 1.5 mm, for example, has a narrower corrugation than a fine corrugated board with a thickness of 2.5 mm. The corrugation type or the size of the corrugation is indicated by letters. You will find the following types of corrugation in our assortment:

|

Wave type |

Name |

Flute pitch (mm) |

Flute height h (mm) |

|---|---|---|---|

|

A |

Coarse flute |

7,9 – 10,0 |

4,0 – 5,0 |

|

C |

Medium wave |

6,5 – 7,9 |

3,1 – 4,0 |

|

B |

Fine flute |

4,8 – 6,5 |

2,2 – 3,1 |

|

E |

Micro wave |

2,6 – 3,5 |

1,0 – 1,9 |

|

F |

Nano wave |

1,8 – 2,6 |

0,6 – 1,0 |

How to take full advantage of the stability of corrugated board

Since the wave always has a direction, there are quite clear differences in the stability with regard to the direction of the load. Corrugated board is often surprisingly stable at right angles to the flute, but parallel to the flute it buckles much faster. This difference always becomes relevant when corrugated board is used constructively. When building a playhouse for children, it is therefore worth thinking about the direction in which the corrugated structure will be installed.

Processing - You can use it to process your corrugated board

Corrugated board such as paper is processed: cutting with scissors or cutters, gluing with glue, paper glue, all-purpose glue or staple. You can coarsely fold the corrugated board by pressing in the cover paper, which should lie inside after folding, for example with a folding bone along a ruler. Now you can fold an angle along the pressed in line. If the corrugated board is to be coloured, it is recommended to use full and tinted colours, as they are also applied to wallpaper or handicraft or poster colours. But beware: If the corrugated board is to be given a new colour over a large area, it tends to bend. Therefore, it should always be treated in the same way on both sides. And again, attention: corrugated board is sharper than you think! No shipping employee who hasn't already cut his way through corrugated board ...