100% recycled, easy to recycle

Water-based bonding

Plastic-free alternative to Kapa

Dimensionally stable (can also be stored upright)

Easy to dispose of by type

| Article No. | |

|---|---|

| Material | 100% recycled cardboard, FSC certified, water-based adhesive |

| Color | black/black |

| Lamination | cardboard (350 g/m², both sides printable) |

| Core | recycled cardboard, honeycomb structure (HoneyComb) |

| Tolerances | ± 2.0 mm (length and width at 750 x 1000) and ± 0.3 mm (thickness) respectively |

| Load capacity | up to 6 kg/m² |

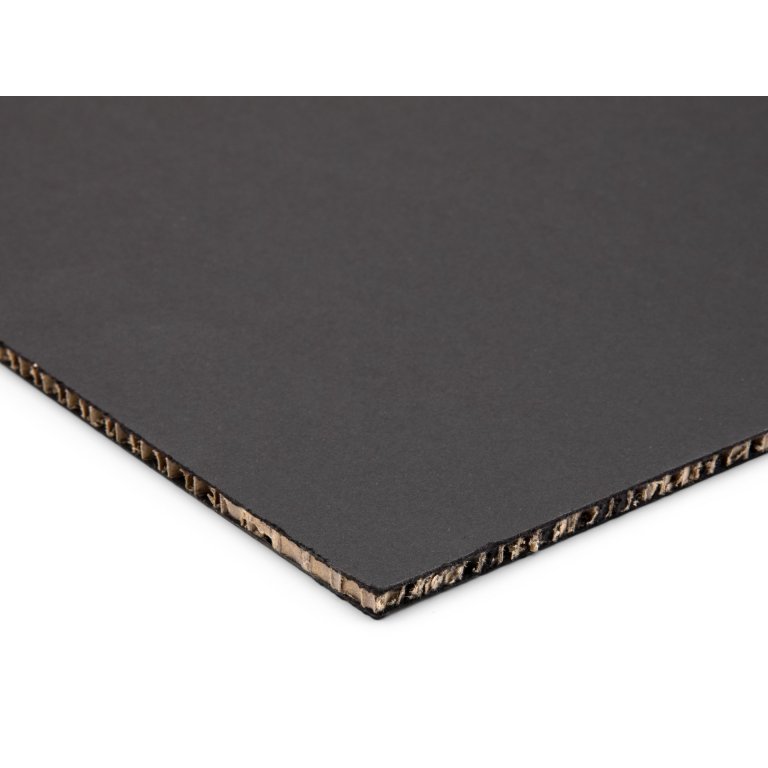

Here comes our thinnest cardboard honeycomb board: Only 5mm thick and made from 100% recycled paper. This makes the lightweight and bend-resistant panel a plastic-free and more environmentally friendly alternative to the black Kapa Graph sandwich panel. With their matt black surfaces, they are well suited as presentation material or moderation wall, for example for workshops and exhibitions. Thanks to the thick cardboard cover, the honeycomb core does not show through when photos or plans are mounted. Counter-laminating is recommended, as with all thin boards, if you value absolute flatness of the board.

The core of the thin board consists of a hexagonal honeycomb structure. This ensures - just as with the thicker cardboard honeycomb panels - that the panel has a high bending stiffness despite its low weight and that the cover layers are protected against dents and damage. Both sides of the black cardboard honeycomb panel can be printed using UV direct printing in a flatbed printer. Cutting is possible with cutter, circular saw, jigsaw and fretsaw, but also with large cutting plotters.

Cardboard honeycomb panels consist of two cover layers and a core of upright cardboard webs. In the core, they differ fundamentally in the arrangement or structure of the connecting webs between the cover layers. The designations "Sinus" and "HoneyComb" are derived from this. In the case of the boards designated HoneyComb, the cardboard webs form a honeycomb structure in the core. In the case of the boards designated Sinus, the cardboard webs are in a corrugated form between the cover layers, comparable to the way they are located in corrugated board. More common are the cardboard honeycomb boards with the honeycomb core, hence the name "honeycomb cardboard". The panels with the corrugated core are more resilient, mainly because there are simply more webs between the cover layers. Thus, the core of the cardboard honeycomb panel Sinus is also somewhat heavier. In material development, the cardboard honeycomb panel is the constructive solution of an optimization process. The task of developing a panel with the highest possible load-bearing capacity using the least amount of material at the lowest possible cost led to this result. The panels are light, load-bearing and resistant to bending. In addition, the board can be completely recycled as paper waste after use without further separation.

The main areas of application for cardboard honeycomb panels are derived from the advantages presented. They are often used as a middle layer in sandwich panels. For this purpose, they are coated with any desired material on both sides. In this way, panels for door panels and furniture are produced. The purity of the material is lost, but furniture and doors are usually in use for a long time, so that sustainability is more a result of the life cycle and the low material input than of the sorted disposal and possible recycling. The other main application is protective packaging for medium-weight goods in transit. Furniture, for example, can be shipped very well in cardboard boxes in which it is protected by a piece of cardboard honeycomb panel in the crucial places (for example, at the edges). Even if the protection is damaged by external force, it does not completely lose its effect and the furniture arrives intact in most cases.

You can use cardboard honeycomb panels in the construction of fair and exhibition buildings, as well as in the construction of furniture and stages. They are also suitable as a light, mobile partition or presentation wall, for printing and as a painting surface. Please note that, depending on storage and transport, the sheets are usually not 100% flat. In order to print on them with plate printers or similar, the plates should be fixed beforehand.

Free standard delivery within Germany and free collection from Modulor in Berlin for orders over 89 €.

5,95 € shipping costs, if order value is less than 89 € (DE)

2,95 € for pick-up at the store in Berlin, if order value is less than 89 €

Express and forwarding shipping

From 19 € express surcharge you will receive your order particularly quickly with standard shipping within Germany.

From 69€ is the cost of shipping within Germany. You can recognize articles with forwarding shipping in the store by the truck symbol .

Especially for Berlin

From 34.90 € courier shipping for standard and forwarding goods.

- Free returns for standard shipping within Germany

- Extended, voluntary return policy of 30 days for complete, undamaged goods in their original packaging

- You are responsible for the cost of returns for forwarding goods and returns from a country outside Germany

Excluded from returns

Excluded from returns are sections of rolled goods, cut-to-size pieces and other goods made especially for you, as well as used goods, newspapers, magazines and periodicals, Modulor vouchers and items that we do not carry in our range but have ordered at your request.

Good to know: The furniture variants in our configurators that can be delivered quickly are not cut to size, but standard formats that can be returned.

Via delle Industrie, 6

24034 Cisano bergamasco

Italy

[email protected]

100% recycled, easy to recycle

Water-based bonding

Plastic-free alternative to Kapa

Dimensionally stable (can also be stored upright)

Easy to dispose of by type

| Article No. | |

|---|---|

| Material | 100% recycled cardboard, FSC certified, water-based adhesive |

| Color | black/black |

| Lamination | cardboard (350 g/m², both sides printable) |

| Core | recycled cardboard, honeycomb structure (HoneyComb) |

| Tolerances | ± 2.0 mm (length and width at 750 x 1000) and ± 0.3 mm (thickness) respectively |

| Load capacity | up to 6 kg/m² |

Here comes our thinnest cardboard honeycomb board: Only 5mm thick and made from 100% recycled paper. This makes the lightweight and bend-resistant panel a plastic-free and more environmentally friendly alternative to the black Kapa Graph sandwich panel. With their matt black surfaces, they are well suited as presentation material or moderation wall, for example for workshops and exhibitions. Thanks to the thick cardboard cover, the honeycomb core does not show through when photos or plans are mounted. Counter-laminating is recommended, as with all thin boards, if you value absolute flatness of the board.

The core of the thin board consists of a hexagonal honeycomb structure. This ensures - just as with the thicker cardboard honeycomb panels - that the panel has a high bending stiffness despite its low weight and that the cover layers are protected against dents and damage. Both sides of the black cardboard honeycomb panel can be printed using UV direct printing in a flatbed printer. Cutting is possible with cutter, circular saw, jigsaw and fretsaw, but also with large cutting plotters.

Cardboard honeycomb panels consist of two cover layers and a core of upright cardboard webs. In the core, they differ fundamentally in the arrangement or structure of the connecting webs between the cover layers. The designations "Sinus" and "HoneyComb" are derived from this. In the case of the boards designated HoneyComb, the cardboard webs form a honeycomb structure in the core. In the case of the boards designated Sinus, the cardboard webs are in a corrugated form between the cover layers, comparable to the way they are located in corrugated board. More common are the cardboard honeycomb boards with the honeycomb core, hence the name "honeycomb cardboard". The panels with the corrugated core are more resilient, mainly because there are simply more webs between the cover layers. Thus, the core of the cardboard honeycomb panel Sinus is also somewhat heavier. In material development, the cardboard honeycomb panel is the constructive solution of an optimization process. The task of developing a panel with the highest possible load-bearing capacity using the least amount of material at the lowest possible cost led to this result. The panels are light, load-bearing and resistant to bending. In addition, the board can be completely recycled as paper waste after use without further separation.

The main areas of application for cardboard honeycomb panels are derived from the advantages presented. They are often used as a middle layer in sandwich panels. For this purpose, they are coated with any desired material on both sides. In this way, panels for door panels and furniture are produced. The purity of the material is lost, but furniture and doors are usually in use for a long time, so that sustainability is more a result of the life cycle and the low material input than of the sorted disposal and possible recycling. The other main application is protective packaging for medium-weight goods in transit. Furniture, for example, can be shipped very well in cardboard boxes in which it is protected by a piece of cardboard honeycomb panel in the crucial places (for example, at the edges). Even if the protection is damaged by external force, it does not completely lose its effect and the furniture arrives intact in most cases.

You can use cardboard honeycomb panels in the construction of fair and exhibition buildings, as well as in the construction of furniture and stages. They are also suitable as a light, mobile partition or presentation wall, for printing and as a painting surface. Please note that, depending on storage and transport, the sheets are usually not 100% flat. In order to print on them with plate printers or similar, the plates should be fixed beforehand.

Free standard delivery within Germany and free collection from Modulor in Berlin for orders over 89 €.

5,95 € shipping costs, if order value is less than 89 € (DE)

2,95 € for pick-up at the store in Berlin, if order value is less than 89 €

Express and forwarding shipping

From 19 € express surcharge you will receive your order particularly quickly with standard shipping within Germany.

From 69€ is the cost of shipping within Germany. You can recognize articles with forwarding shipping in the store by the truck symbol .

Especially for Berlin

From 34.90 € courier shipping for standard and forwarding goods.

- Free returns for standard shipping within Germany

- Extended, voluntary return policy of 30 days for complete, undamaged goods in their original packaging

- You are responsible for the cost of returns for forwarding goods and returns from a country outside Germany

Excluded from returns

Excluded from returns are sections of rolled goods, cut-to-size pieces and other goods made especially for you, as well as used goods, newspapers, magazines and periodicals, Modulor vouchers and items that we do not carry in our range but have ordered at your request.

Good to know: The furniture variants in our configurators that can be delivered quickly are not cut to size, but standard formats that can be returned.

Via delle Industrie, 6

24034 Cisano bergamasco

Italy

[email protected]