| Article No. |

|---|

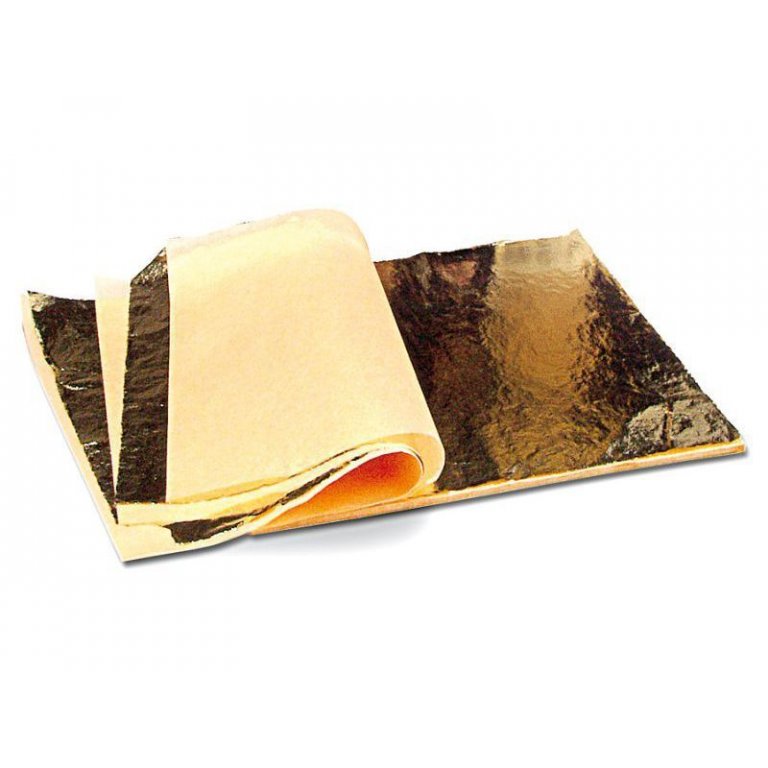

shiny, very good quality, th = app. 0.5 µm, loose, with tissue paper intermediate sheets, comes in self-seal bag

Metal leaf, which is also often referred to as composition gold or schlagmetal, makes it possible to put a beautiful finish on practically every type of surface. It is considerably less expensive than its real relatives gold leaf and silver leaf but nonetheless has an almost identical appearance and, because of its comparatively greater thickness, is even easier to work with. As a rule, metal leaf is only suitable for use indoors.

The metal leaves with the colours antique and middle gold are alloys made from copper and zinc, which means it is basically brass. The greater the proportion of copper, the redder the tone of gold. Even the silver coloured metal leaf, although it is really only aluminium, is hard to distinguish from real silver.

The surface of the object to be worked on must first be cleaned enough that it is free of grease (e.g. with acetone– attention!; make a preliminary test). Absorbent substrates have to be processed further before being worked on (see Information at gilding size). Finally, depending on the substrate and the type of gilding, a gilding size with either low or high viscosity must be carefully applied with, preferably, an application brush.

Then the metal leaf, in either small or large pieces, should be carefully pressed into place with a soft, dry brush (e.g. a shaping brush) or a cloth. During this procedure, as much attention as possible should be given to avoiding any contact between the gilding size and the brush. A cotton swab can be used for applying the metal leaf to hard to reach places. The metal leaf will adhere exclusively to places where the gilding size has been applied. Because the metal leaves cannot be placed exactly edge to edge, it should still be laid with the least amount of overlap possible (save the gold!) and any ensuing creases smoothed out with a soft brush. Only when the whole surface has been filled and allowed to air out, should any remaining gold be simply brushed away with a brush or a cloth.

Only after being allowed to completely dry (approximately 12 hours) can the surface be carefully polished with a soft cloth or cotton ball in order to further improve the appearance of the new surface. Objects that have received this treatment should subsequently be sealed with finishing varnish but only after at least a three day wait (otherwise dark spots may appear on the metal finish). Without this clear varnish, oxidation will occur after a certain amount of time depending on the type of metal leaf and this will produce various kinds of patina which can be very attractive in their own right. 5 leaves of metal leaf will cover an area of about 0.4 m².

Free standard delivery within Germany and free collection from Modulor in Berlin for orders over 89 €.

5,95 € shipping costs, if order value is less than 89 € (DE)

2,95 € for pick-up at the store in Berlin, if order value is less than 89 €

Express and forwarding shipping

From 19 € express surcharge you will receive your order particularly quickly with standard shipping within Germany.

From 69€ is the cost of shipping within Germany. You can recognize articles with forwarding shipping in the store by the truck symbol .

Especially for Berlin

From 34.90 € courier shipping for standard and forwarding goods.

- Free returns for standard shipping within Germany

- Extended, voluntary return policy of 30 days for complete, undamaged goods in their original packaging

- You are responsible for the cost of returns for forwarding goods and returns from a country outside Germany

Excluded from returns

Excluded from returns are sections of rolled goods, cut-to-size pieces and other goods made especially for you, as well as used goods, newspapers, magazines and periodicals, Modulor vouchers and items that we do not carry in our range but have ordered at your request.

Good to know: The furniture variants in our configurators that can be delivered quickly are not cut to size, but standard formats that can be returned.

Differences and changes in colour are not grounds for customer complaint regarding metal leaf.

| Article No. |

|---|

shiny, very good quality, th = app. 0.5 µm, loose, with tissue paper intermediate sheets, comes in self-seal bag

Metal leaf, which is also often referred to as composition gold or schlagmetal, makes it possible to put a beautiful finish on practically every type of surface. It is considerably less expensive than its real relatives gold leaf and silver leaf but nonetheless has an almost identical appearance and, because of its comparatively greater thickness, is even easier to work with. As a rule, metal leaf is only suitable for use indoors.

The metal leaves with the colours antique and middle gold are alloys made from copper and zinc, which means it is basically brass. The greater the proportion of copper, the redder the tone of gold. Even the silver coloured metal leaf, although it is really only aluminium, is hard to distinguish from real silver.

The surface of the object to be worked on must first be cleaned enough that it is free of grease (e.g. with acetone– attention!; make a preliminary test). Absorbent substrates have to be processed further before being worked on (see Information at gilding size). Finally, depending on the substrate and the type of gilding, a gilding size with either low or high viscosity must be carefully applied with, preferably, an application brush.

Then the metal leaf, in either small or large pieces, should be carefully pressed into place with a soft, dry brush (e.g. a shaping brush) or a cloth. During this procedure, as much attention as possible should be given to avoiding any contact between the gilding size and the brush. A cotton swab can be used for applying the metal leaf to hard to reach places. The metal leaf will adhere exclusively to places where the gilding size has been applied. Because the metal leaves cannot be placed exactly edge to edge, it should still be laid with the least amount of overlap possible (save the gold!) and any ensuing creases smoothed out with a soft brush. Only when the whole surface has been filled and allowed to air out, should any remaining gold be simply brushed away with a brush or a cloth.

Only after being allowed to completely dry (approximately 12 hours) can the surface be carefully polished with a soft cloth or cotton ball in order to further improve the appearance of the new surface. Objects that have received this treatment should subsequently be sealed with finishing varnish but only after at least a three day wait (otherwise dark spots may appear on the metal finish). Without this clear varnish, oxidation will occur after a certain amount of time depending on the type of metal leaf and this will produce various kinds of patina which can be very attractive in their own right. 5 leaves of metal leaf will cover an area of about 0.4 m².

Free standard delivery within Germany and free collection from Modulor in Berlin for orders over 89 €.

5,95 € shipping costs, if order value is less than 89 € (DE)

2,95 € for pick-up at the store in Berlin, if order value is less than 89 €

Express and forwarding shipping

From 19 € express surcharge you will receive your order particularly quickly with standard shipping within Germany.

From 69€ is the cost of shipping within Germany. You can recognize articles with forwarding shipping in the store by the truck symbol .

Especially for Berlin

From 34.90 € courier shipping for standard and forwarding goods.

- Free returns for standard shipping within Germany

- Extended, voluntary return policy of 30 days for complete, undamaged goods in their original packaging

- You are responsible for the cost of returns for forwarding goods and returns from a country outside Germany

Excluded from returns

Excluded from returns are sections of rolled goods, cut-to-size pieces and other goods made especially for you, as well as used goods, newspapers, magazines and periodicals, Modulor vouchers and items that we do not carry in our range but have ordered at your request.

Good to know: The furniture variants in our configurators that can be delivered quickly are not cut to size, but standard formats that can be returned.

Differences and changes in colour are not grounds for customer complaint regarding metal leaf.