Linoleum tabletop

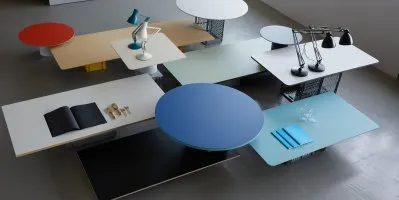

Natural, robust, easy to clean. The linoleum table top is the most colourful and stylish table top in our range. You can put together your own unique linoleum table top from numerous edge and corner variations as well as colour options. Over 1000 variations are possible with Modulor.

Our colour samples will help you choose the colour of your table top.

Why choose a linoleum tabletop?

Linoleum is a natural material made from linseed oil, jute, wood flour and limestone powder. This makes the board biodegradable. The coating has a pleasant, matt and non-slip feel and is heat-resistant up to 70°C for short periods. The surface also has an antibacterial effect. This makes a linoleum table top ideal for kitchens and dining areas.

Linoleum table tops are also perfect for the office or conference room. The pleasant feel is firm yet elastic. This makes a linoleum desk top the ideal work surface for writers and draughtsmen. In technical environments such as server rooms or production areas, linoleum protects against electrostatic charge.

Despite its resilience, it is important to avoid point loads on linoleum. Pens or other sharp objects should not be pressed too firmly onto the linoleum table top. Otherwise the surface may be damaged. To prevent the linoleum from discolouring, we recommend using coasters under terracotta, clay and metal objects that are to be placed on the table top.

Incidentally, the linoleum table top is not suitable for use in rooms with high humidity, such as bathrooms.

Small selection guide

How do you find the right linoleum panel for you? With 21 linoleum colours, 3 high-quality sheet materials and numerous edging, edge and corner options, it's easy to lose track. We explain below which sheet material is suitable for which purpose.

1. with edge banding

- Material: Fir wood slatted board with edge banding made of real wood or ABS plastic

- Maximum dimensions: 320 x 180 cm

- Thickness incl. linoleum: 30 mm

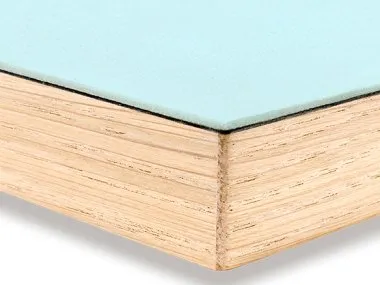

2. multiplex birch panel

- Material: Sanded multiplex birch board with straight or bevelled board edge (25° bevel)

- Maximum dimensions: 300 x 150 cm

- Thickness incl. linoleum: 20 mm or 26 mm

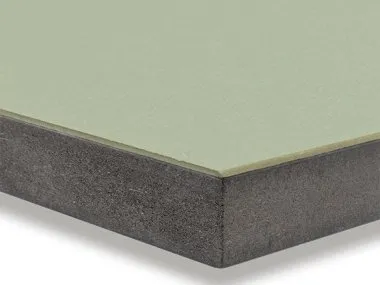

3. valchromat MDF board

- Material: Sanded Valchromat MDF board with straight or bevelled board edge (25° bevel)

- Maximum dimensions: 240 x 180 cm

- Thickness incl. linoleum: 21 mm

1. Rod board with edge banding

The core of our linoleum table top with edge banding consists of a 28 mm thick fir wood strip board. The composition of approx. 5 mm wide fir wood sticks glued together makes the linoleum table top extremely dimensionally stable. It is therefore also suitable for large-format tables. The sides of the table top are covered with an edge band made of real wood or ABS plastic. There is a choice of 6 real wood edgebands (walnut, smoked oak, larch, multiplex birch, oak and ash), one ABS edgeband in black and one ABS edgeband in the same colour as the linoleum.

What is the chopstick panel with edgeband suitable for?

All table frames in the Modulor series (E2, M, T, Y) can be configured with the rod table top with edging. Thanks to the material processing and 30 mm tabletop thickness, this tabletop is also suitable for large-format tables. With the numerous possible combinations of edging and table top, you can put together the writing, drawing, office, dining and kitchen table of your choice.

2. Top made of multiplex birch

The multiplex birch table top consists of several layers of birch veneer. The distinctive "striped" edge of the table top is created when the individual layers of veneer are glued together. They are pressed crosswise and glued together to make them waterproof. The grain not only provides aesthetics, but also robustness: a laminated wood top warps less. The edge of the linoleum table top is simply finely sanded to emphasise the striped pattern. Despite the unpainted edge, the multiplex board is moisture-repellent and very resistant. The optional bevelled edge gives the table top a light and delicate appearance.

What is the multiplex birch panel suitable for?

All table frames in the Modulor series (E2, M, T, Y) can be combined with a multiplex top. The multiplex birch tops are therefore suitable for desks, drawing tables, work tables, office tables, dining tables and kitchen tables. Table frames with a supporting frame or top reinforcements are required for 20 mm thick tops. Large-format conference tables are also possible with the 26mm multiplex tops.

3. Valchromat MDF

Valchromat is a water-repellent, coloured and highly compressed wood fibreboard (MDF). The glued fibres are pressed into a dense, very rigid, homogeneous board. The edges of the MDF are untreated and open-pored. Despite its raw and direct nature, the finely sanded material is moisture-repellent and resistant. The edge can optionally be bevelled by 25°. This gives the linoleum table top an unobtrusive and light appearance.

What is the Valchromat MDF board suitable for?

The MDF table top can be mounted on all Modulor series table frames (E2, M, T, Y) with a supporting frame or table top reinforcements. The additional support ensures that the table top does not deform or sag. It is therefore suitable for small to medium-sized desks, drawing tables, work tables, office tables, dining tables and kitchen tables.

The combination wonder linoleum table top

16 colours

With its pleasantly warm feel, the linoleum table top is the perfect base for desks and work tables. A total of 22 colours ensure a modern and varied interior design to suit your individual taste.

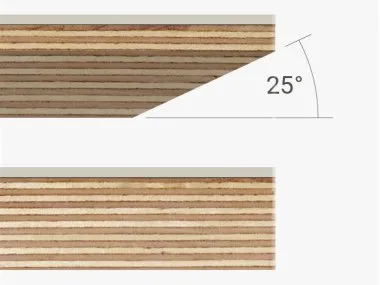

2 panel edges

In addition to the variety of linoleum colours and high-quality panel materials, Modulor also offers the shape of the panel edge. In addition to classic straight edges, we also offer a special bevelled edge. The 25° bevelled edge makes the robust table top appear thinner, more delicate and almost floating. The bevelled edge is available for the multiplex birch and Valchromat MDF table top cores.

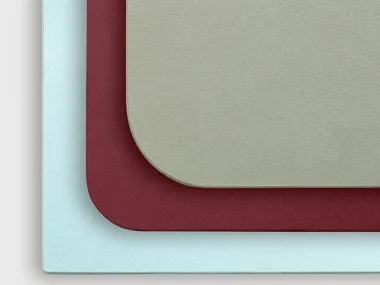

3 corner radii

Not only with edges, but also with corners. The smallest corner radius of 3 mm corresponds to a classic table top corner. The two more rounded corners (25 mm or 50 mm corner radius) give the linoleum table top a less solid and softer appearance. In this way, they also support the reduced shape of the bevelled edge. The 25 mm and 50 mm corner radii are only available for the Multiplex birch and Valchromat MDF table top cores.

3 cable bushings

No more tangled cables! A cable aperture bundles all device, charging and lamp cables and keeps the table tidy. Or you can use the cable opening creatively - as a drinks holder or as a direct route to the wastepaper basket below.

The largest is the Ø 80 mm hole milling without edging. It exposes the various layers of the linoleum table top. Those who prefer a less raw look can opt for a cable aperture with aluminium edging (Ø 74 mm) or a cable aperture with a lockable cover and plastic bristles (Ø 74 mm). The bristles prevent cables from slipping through or out of place, even when devices are removed.

No fear of a yellow tinge

Linoleum is a natural material. Linoleum table tops in light colours in particular sometimes undergo post-oxidation. This manifests itself in a slight yellow tinge, which is harmless and disappears when exposed to UV light. If the linoleum table top is used as a desk or work table, the temporary discolouration occurs under a computer, printer or similar. As soon as the equipment and office utensils are removed and sunlight falls on the surface, the original colour of the linoleum returns. The yellow colour cannot be removed with cleaning agents.

How to care for your linoleum tile properly

How and how often you need to clean and maintain your linoleum tabletop depends on how often it is used and how dirty it is. Spilt drinks, sauces, ice cream etc. should be wiped up immediately with a soft cloth. This will prevent stains.

Care for your linoleum table top with care. The material is quickly "over-cared for". Oily products in particular can clog it and leave shiny spots. We therefore recommend using a cloth to quickly wipe off such products.

Dust, crumbs or other loose dirt particles, on the other hand, can be easily removed at any time with an ordinary dust cloth.

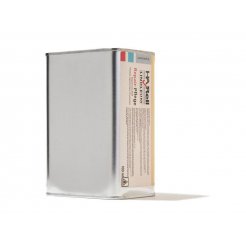

If dirt has accumulated on the linoleum surface, we recommend using a cleaning agent specifically for linoleum table tops (e.g. Harell cleaning agent for linoleum). Linoleum is sensitive to alkaline solutions. Therefore, choose a cleaning agent without aggressive alkalis. The dirt can be wiped off the linoleum tabletop with a lint-free cloth and the cleaning agent dissolved in a little water. For stubborn stains, the cleaning agent should be used undiluted and the cleaned surface wiped with a cloth soaked in water.

Avoid disinfectants that are not specifically suitable for linoleum. They can discolour the material and leave permanent stains. Be careful with products containing solvents such as nail varnish remover! These attack the surface of the linoleum table top and leave permanent marks.

Discover all table tops from Modulor

Linoleum is not the right surface material for your requirements? Then take a look at our other table tops. With our affordable melamine, hard-wearing HPL or classic solid wood table tops, everyone will find the right table top for them. And they all have one thing in common: they can be configured in colour, shape and size to suit your requirements.